Looking For Namkeen Packing Machine?

But Not Sure Of:

But Not Sure Of:

Most important is the type of machine that has been selected for the packing application. Selecting the wrong machine can cost lakhs of rupees wasted and loss of morale. Usually no business owner would like to make a wrong choice. It is only due to lack of understanding that causes this

When selecting a packing machine, one of the first steps is to accurately assess your production volume and speed requirements. This involves understanding how many units you need to package per day, week, or month, and how quickly the machine needs to operate to meet these demands. Next, assess your production volume.

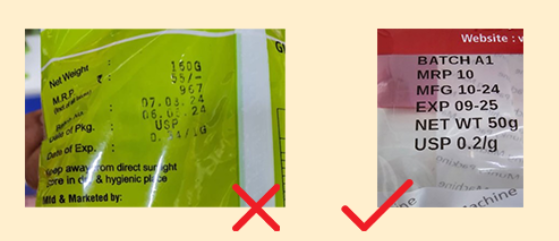

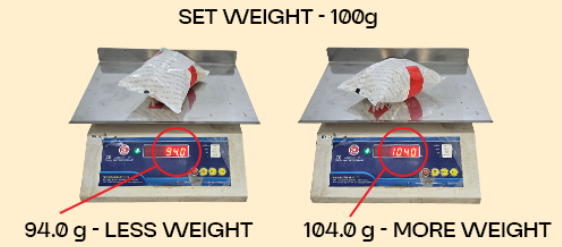

As per the Legal Metrology Act, the weights and measures department has specified a tolerance limit for net weight being packed. It is an acceptable norm in the market to fill slightly more than the weight specified. This excess weight if not controlled can cause a big loss. In one corporate it resulted in a massive saving of Rs. 2.30 Crores per month.

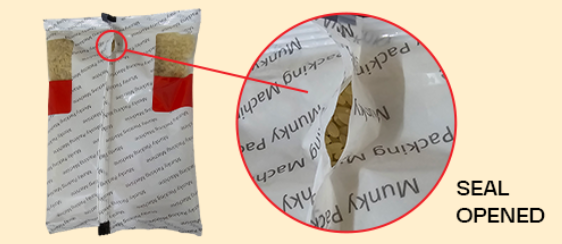

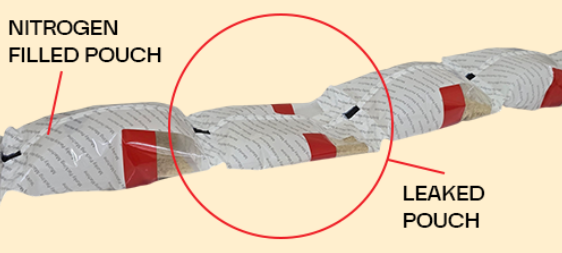

Sealing is a critical aspect of the whole packing process. Improper sealing results in leakage, the outside atmosphere comes in contact with packed material and it gets bad even when it is still on the shelf of the retail counter. Which brings down the brand reputation and the retailers lose faith.

Some designs of machines are such that adjusting the laminate in the pouch former is a tedious process and getting the correct shape and sealing at the correct position is a challenge. And a lot of material is wasted during machine setup.

If you have multiple items to be packed, it may not be commercially feasible to dedicate one machine to one SKU. So machine setup for different pouch sizes and different net weights is an important aspect. If it is difficult to change over then a considerable amount of production time and manpower is wasted which results in lower efficiency and loss of money. In some cases it may be as high as Rs. 3540 per change over.

Cheap machines will make a pouch, no doubt. But the question is how does your pouch look in front of the established brands that are already available in the same market? Once the investment is done then there is no going back. It will be a costly affair to replace the machine and get one which makes pouches that are aesthetically appealing.

Simple to operate machines do not require expensive operators! Maintenance is another aspect that cannot be neglected. If there is a regular breakdown then not only does the production suffer, but also the market demand cannot be fulfilled and it is very expensive on the pocket.

Choose a manufacturer known for excellent customer service and technical support. Access to expert advice, troubleshooting assistance, and timely repairs can prevent prolonged downtime and production losses.

By not solving these problems you will lose upto Rs. 29 Lakh, or in the worst case scenario you will have to shut down your business with heavy losses.

Using Our Machine

Using Our Machine

Rs. 856 CRORE

Pouches Packed

Rs. 23.90 Crore

Worth Of Laminate Saved

12845 Metric Ton

Material Saved

Rs. 25.70 Crore

Worth Of Manpower Saved

Rs. 856 CRORE

Pouches Packed

Rs. 23.90 Crore

Worth Of Laminate Saved

12845 Metric Ton

Material Saved

Rs. 25.70 Crore

Worth Of Manpower Saved

Check Out Namkeen Packing Video

Brands That Trust Us

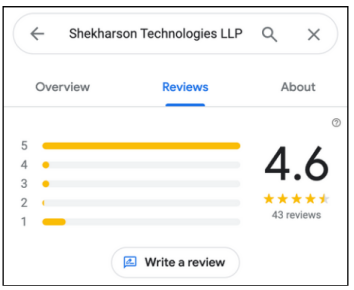

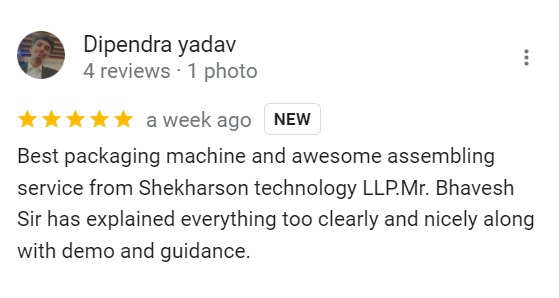

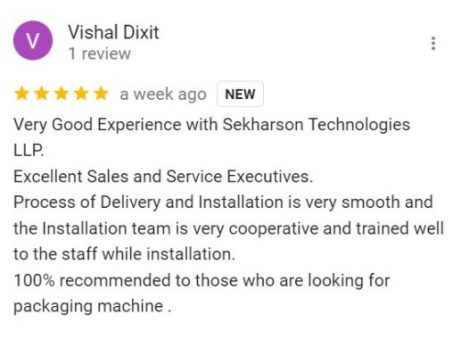

What our Customers Have to Say

Who We are

Still Looking for more information?

Unlock exclusive insights with our free ebook! Discover expert tips, strategies, and secrets to elevate your success. Download now and transform your knowledge into action. Don’t miss out.

Fill Form to Download eBook

Shekharson Technologies LLP

MUNKY PACKING MACHINES

B-10 & 9, FIT, Sec. 57

Faridabad, Haryana