Popcorn Packing Machine

With growing awareness in the area of health, Popcorn is becoming a hot favourite snack that consumers are choosing over other options. It has opened up a new area for manufacturers and new opportunity in the field of food packing.

Packing popcorn has some challenges owing to its characteristic.

1. Very light in weight

2. Gets crushed easily

3. Occupies more volume

Typically popcorn is sold in nett weight range from 20gm to 100g. This depends on the strategy and marketing of the manufacturer.

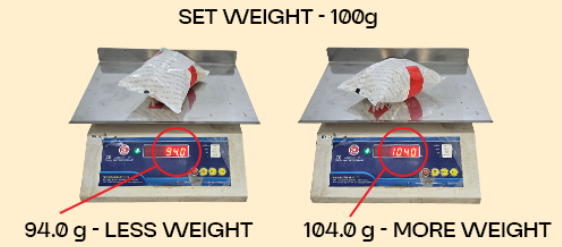

When packed in a volumetric cup filler it poses challenges as it is not so free flowing and the volumetric cups do not fill properly and even if they fill properly chances are that they may not empty out the whole cup in the pouch this causes a weight variation in the pouch of the popcorn packing.

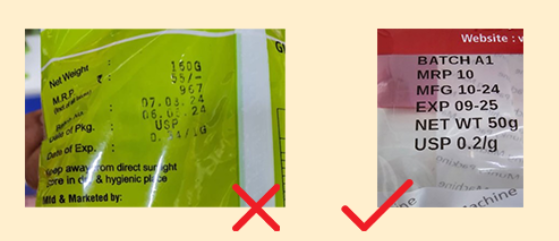

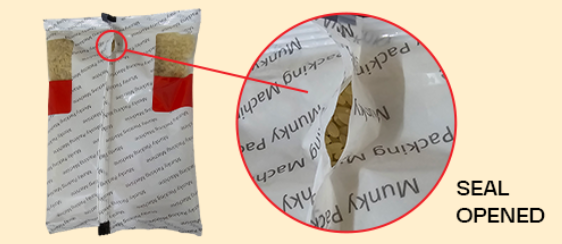

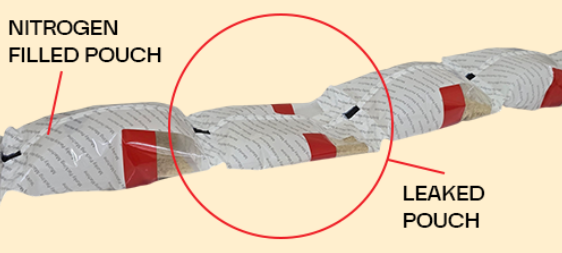

Also as these items are sold in small pouches there is existing competition from other manufacturers so the quality of packing in terms of sealing, finishing of the pouch after packing, nitrogen filling and leakage are major areas of concern to be successful in the popcorn packing.

Manufacturers want to pack multiple nett weights in the same machine without change parts in the filling system and the cup fillers cannot handle this kind of product effectively.

The change over from one weight setting to the other must be easy and the machine should be able to pack other items also apart from popcorn.

Automatic Popcorn Packing Machine

Semi Automatic Popcorn Packing Machine

Connect with us for FREE Consultation or to Download Catalogue

Oops! We could not locate your form.

*This information will remain confidential.

Solution – Popcorn Packaging Machine

The most appropriate solution for packing popcorn is a linear weigher coupled with a full pneumatic bagger. The below video gives the details of working and operation and all aspects of the popcorn packing machine.

Different nett weights can be set in this popcorn packaging machine and it can store upto 10 different program settings and the setting can be recalled with just a few clicks on the display panel.

Different pouch sizes can be packed in the same packing machine only the chute is to be changed every time the pouch width changes and if the pouch width is the same and only the pouch length is varying then there is no need to change the chute of the popcorn packaging machine.

As the popcorn has different particle sizes the bulk density of popcorn at the time of packing is not consistent so a volumetric filling system will not work well for this application. When filled in a weigh filler the variation in the bulk density does not pose any challenge as it is filling on the basis of weight.

It is available in many variants from semi automatic to fully automatic version. The fully automatic machine also has some variants in terms of number of weighing heads and it is available in two weighing head and four weighing head depending on the speed of packing that is required. The semi automatic popcorn packaging machine has the same filling system as compared to its fully automatic counterpart. The only difference is that the bagger is removed and the sealing is done in a separate sealer. This system is effective where the production level is around 2000 to 5000 bags per day and the product is to be packed in individual packets and not in chain form. It is a very versatile machine and can be used to pack many different items in the same machine.

Popcorn Packing Machine Price

Please contact us by clicking below link to get Popcorn Packing Machine Price In India.

*

![]()

+91-9599919442