By not solving these problems, you may lose upto 22.6 Lakh Rs/year or may even be forced to shut down your business.

Research has Shown 48% businesses shutdown in first 3 years because of one or more of the above 9 reasons

Using our machine 856 Crore Pouches packed

We Saved 12,845 MT of Raw material

1035 MT Laminate Saved amounting to Rs. 23.90 Cr.

62 Lakh Man Hours Saved amounting to Rs. 25.76Cr

Benefits of our Pouch Packing Machine

Excellent Weight Accuracy

Excellent Weight Accuracy Leak Proof Sealing

Leak Proof Sealing Pack multiple weights in same machine

Pack multiple weights in same machine Programmable pouches in one strip

Programmable pouches in one strip High Speed Production

High Speed Production Multiple models for different business needs

Multiple models for different business needs

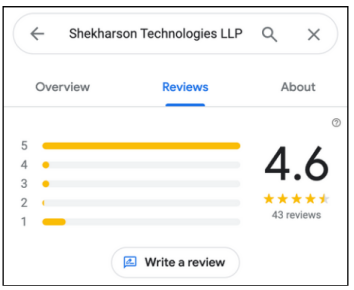

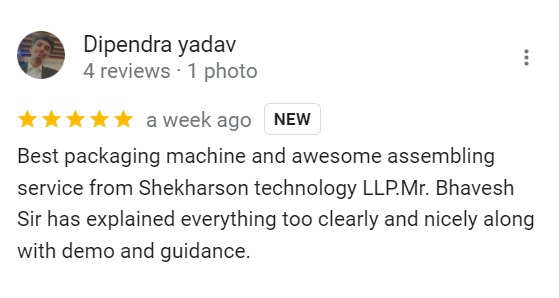

Satisfied Customers

What our customers have to say!

To connect with one of our application experts please fill the form below and we will call you back shortly

Want a call back from our experts? Fill the form below

Not sure about how to select your pouch packing machine?

Download this easy to read eBook for FREE

Understand how you can maximise your pouch packing investment and choose the best pouch packing machine for your business

Get this FREE ebook in English & Hindi

Feel free to connect with our experts +91-9599919442