Dry fruit Packing Machine

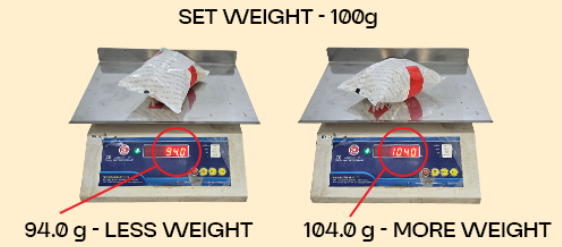

In dry-fruits the most common items that are packed are Almonds and Cashews. Dry-fruits like cashews and almonds are expensive in nature. Moreover, they are heavy in particle size as compared to grains or other snack food items. And are usually packed in the range of 50gm to 1kg of pouches. As dry fruits are expensive it is necessary that the packed weight is within permissible limits. Otherwise it can cause a huge dent in the pocket. The rising demand and growing health consciousness is putting a constant pressure on manufacturers. Therefore, manufacturers must pack more and more with better weight accuracy and improved packing quality.

Manual Packing Process

Most manufacturing companies producing dry fruit in packed form do the packing by hand using a manual process. There is a team of 3-4 people who fill the pouch then weigh, top up the material in the pouch to get the correct weight. Lastly one person seals it in a manual sealer. This has several challenges firstly the manpower is not consistently available. Secondly there is a lot of dependence on few people who are skilled in manual weighing.

Challenges

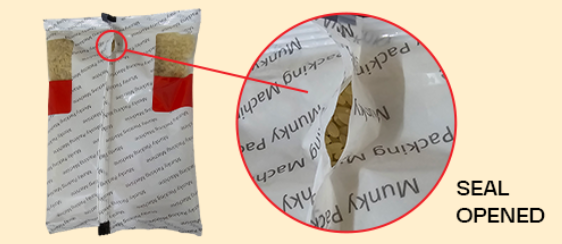

Absenteeism at the time of peak workload is a consistent concern that most manufacturers face. Along with disciplinary issues as only a few people who are skilled in weighing fast can do the job. This poses another challenge that even with skilled there is no control and monitoring over the nett weight which is going in the pouch. As long as some is there to keep a watch the weight accuracy is maintained later it may go more or less. This causes problems in sales as retailers and distributors keep complaining of weight variation and sealing issues and increasing sales becomes a challenge. As long as the production levels are in the range of 500 to 1000 pouches per day the manual system can support it. And there is no harm in the manual system of packing. It is cheap to start with and time to market gets reduced substantially for a startup. But this philosophy itself becomes the bottleneck as soon as the production volumes start to grow. It becomes very important to control the losses in packing cashews and dry fruits and improve the speed and effectiveness of packing to maintain cost competitiveness.

Desire

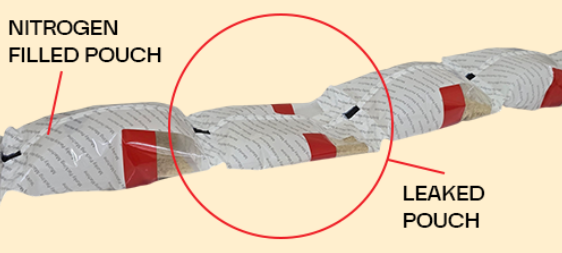

The Focus is now shifting towards saving manpower, removing skill, improving productivity, and saving of material in packing process. Dry fruits packing is done in the range of 50gm to 1kg and one machine should be able to pack this entire weight range. Manufacturers desire that the machine should have the capability of changing over from one weight setting to the other with ease. The accuracy is maintained in the nett weight of the pouch. It should be simple to operate and it should be easy to train a new operator on the machine. For a Dryfruit Packaging Machine to be successful it is important that the packaging machine is able to save extra material from being packed, reduce the time of packing, remove dependence on skill of weighing and packing, perform packaging in a hygienic manner, batch code marking and batch cutting. If the nett weight that is packed in each pouch is less then the distributors and dealers raise a complaint. To take care of this complaint the manufacturers tend to pack more. This additional give away which is more than the acceptable norm becomes a very huge figure at the end of the year. And this becomes the single most critical factor for eroding the profitability. The know more about how this impacts the ROI of packing machine click here.

Solution – Almond and Cashew Packing Machine

Munky manufactures Automatic Cashew Packaging Machine and Automatic Almond Packaging Machine. The below video gives detailed operation and information about dry fruit packing machine. This is a fully automatic packing machine however low cost semi automatic versions are also available which can pack nearly 5000 packs in one day using 2 people.

Operation

In this machine the material is loaded in the top hopper which takes the almonds and cashews down via the vibratory feeders into the weighing pan where it is accurately weighed and then the material is discharged into the bagger where it is sealed in the pouch.

Weights

Different nett weights of almond packing and cashew packing can be done in the same machine and the setting of the parameters can be saved in program memory and any weight setting can be recalled with just a few clicks on the display panel.

Multiple Pouch Sizes

Our dry fruit packaging machine can pack different pouch widths and nett weights. The width of the laminate roll of the pouch varies as the pouch width varies. To change the pouch size the laminate roll and forming chute have to be changed on the machine. Also the corresponding weight setting has to be recalled from the display panel.

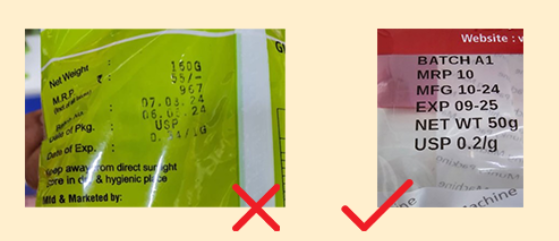

Batch Coding

The machine is fitted with a batch coding unit that is capable of printing multiple lines at the designated location. However optionally one can also opt for ribbon coding unit or TTO Printer or Ink jet printer . The MRP, Lot Code, Date of packing and nett weight can be printed automatically on the pouch.

Output Conveyor

There is an option for an output conveyor which takes the bags out of the machine. To suit different production levels this packing machine is available in different variants ranging from two to four weighing heads.

Semi/Full Auto Versions

The almond and cashew packing machine is also available in a low cost variant ie semi automatic dry-fruit packing machine. This machine utilizes the same filling technology. The only difference is that the bagger has been removed to make it more cost effective. This system is good for a startup unit or a low production unit that packs upto 2000 kgs in one day of 1kg packets. We invite you to speak to our application specialists by filling the contact form. They will analyse your application and suggest to you the most appropriate solution for you.

Our pouch packing machine is customizable and for the same application there are multiple models which can be used. To see which model fits into your budget you may call us on +91-9599919442 or fill the form by clicking here.

For those who like to read, we have a bunch of resources, some of which are FREE that you can find by clicking here or visiting the resources section on this website. For Startups and manual packagers who want to grow their business, we have created an e-Course in the form of a mobile app. Download it FREE here ! Still Looking around for more detailed videos? You may visit our youtube channel, trusted by over 1,30,000 subscribers by clicking here.

Dry fruit Packing Machine

In dry-fruits the most common items that are packed are Almonds and Cashews. Dry-fruits like cashews and almonds are expensive in nature. Moreover, they are heavy in particle size as compared to grains or other snack food items. And are usually packed in the range of 50gm to 1kg of pouches. As dry fruits are expensive it is necessary that the packed weight is within permissible limits. Otherwise it can cause a huge dent in the pocket. The rising demand and growing health consciousness is putting a constant pressure on manufacturers. Therefore, manufacturers must pack more and more with better weight accuracy and improved packing quality.