Vermicelli Packing Machine

Vermicelli is a very light weight material. Since it has a very less diameter and only about an inch in length it has a peculiar flow. On the other hand while packing vermicelli in a cup filler poses the problem of short fills. This happens because of length and diameter of the vermicelli. This causes a lot of variation in the nett weight of the vermicelli being packed, which makes it difficult to pack hence the need of vermicelli packing machine.

Owing to increasing awareness in health consciousness the consumption of vermicelli is increasing. Vermicelli has now found an important place in healthy snacks and breakfast. As the demand of vermicelli is increasing it is posing more pressure on manufacturers to produce and pack at faster rates. Which necessitates a highly effective vermicelli packing machine.

In most of the units manufacturing vermicelli the constraint is in the packing in pouches. It is very important to control the losses in packing vermicelli and improve the speed and effectiveness of packing to maintain cost competitiveness. Focus is on saving manpower, removing skill from vermicelli packing process, reduction in consumption of electricity, and saving of material in packing process.

Vermicelli is usually packed in the range of 50gm to 1kg. And one machine should be able to pack this entire range. Manufacturers of vermicelli desire that the machine should have the capability of changing over from one weight setting to the other with ease and no change parts. Also vermicelli should not get stuck in any part of the machine so that the accuracy is maintained in the nett weight of the pouch. It should be simple to operate and it should be easy to train a new operator on the machine.

Conventionally vermicelli packing is done in many industries manually. A team of 3-5 people fill the pouch manually and then weigh it on a weighing scale and then seal it in a band sealer or an impulse sealer. This system works well as long as the productions are low in the order of 500 to 1000 pouches per day, however as the production increases the team is not able to pack efficiently there are losses due to spillage, inaccuracy in nett weight, high dependence on the skill of the person weighing the product, absenteeism of the critical person doing the weighing. Hygiene is compromised and quality of packing is not up to the mark.

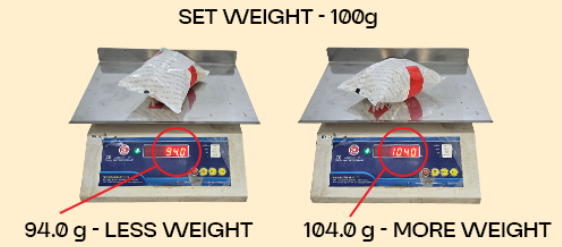

A successful vermicelli packing machine keeps the net weight per pouch in permissible limits, reduces time of packing, reduces dependence on manpower, does hygienic packing. The retailers and distributors complain if the net weight in the pouch is less, further more it has legal implications. To take care of this, manufacturers tend to instruct the operator to pack more in each pouch. Once this kind of instruction is given to the production personnel, there is no control over the upper limit of weight being packed in the pouch. This excess weight that goes in every pouch becomes a very significant figure on an annual basis. And is the single largest factor for the project becoming unprofitable.

Solution – Vermicelli Packaging Machine

We manufacture automatic vermicelli packing machine that fills on the basis of weight. The video given below gives a detailed description of the operation of Automatic Vermicelli Packaging Machine.

This machine has vibratory feeders below the material hopper. The vibratory feeder makes the vermicelli flow freely unlike in a cup filler. After weighing vermicelli discharges through the discharge funnel. There after it falls in the bagger where pouch sealing takes place. The same machine can pack Multiple nett weights. The memory of the machine stores all the setup parameters. Our vermicelli packing machine is capable of packing different pouch widths and nett weights.

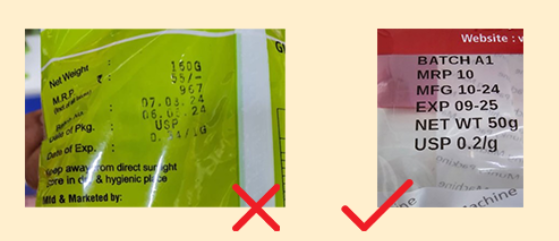

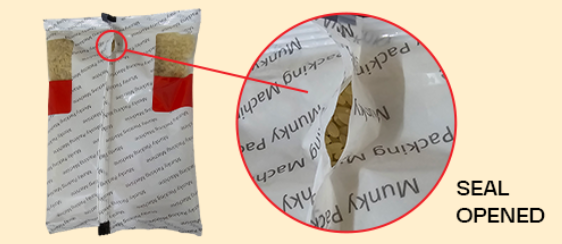

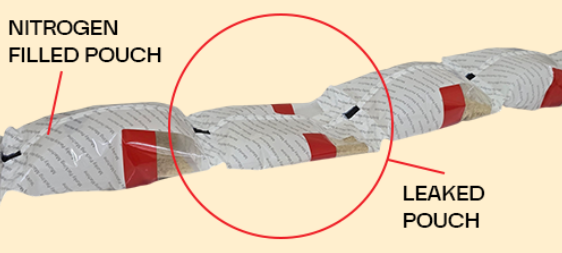

Different forming chutes or forming collars pack pouches of different widths. The eye mark is sensed by a camera for the precise positioning of the horizontal sealing. Nitrogen filling is a user programmable feature, with controls on the display panel. The batch coding unit can print multiple lines on the pouch at designated locations.

In the standard machine a pneumatic coder is provided. However, the ribbon coder comes as an added accessory. The pneumatic batch coding unit is provided for printing upto 4 lines of information, like MRP, Lot Code, Date of Packing and Nett Weight of the pouch. The optional output conveyor pulls out the pouches from the machine.

Automatic Vermicelli Packing Machine is available in different formats with one, two or four weighing heads. The vermicelli packing machine is also available in a low cost variant ie semi automatic vermicelli packing machine. This machine utilizes the same filling technology as the fully automatic counterpart. The only difference is that the bagger has been removed to make it more cost effective. This system is good for a startup unit or a low production unit that packs upto 2000 kgs in one day of 1kg packets. For more information you may contact our solution experts by filling the contact form.

Vermicelli Packing Machine Price

Please contact us by clicking below link to get Price.

For those who like to read, we have a bunch of resources, some of which are FREE that you can find by clicking here or visiting the resources section on this website. For Startups and manual packagers who want to grow their business, we have created an e-Course in the form of a mobile app. Download it FREE here ! Still Looking around for more detailed videos? You may visit our youtube channel, trusted by over 1,30,000 subscribers by clicking here.

Vermicelli Packing Machine

Vermicelli is a very light weight material. Since it has a very less diameter and only about an inch in length it has a peculiar flow. On the other hand while packing vermicelli in a cup filler poses the problem of short fills. This happens because of length and diameter of the vermicelli. This causes a lot of variation in the nett weight of the vermicelli being packed, which makes it difficult to pack hence the need of vermicelli packing machine.