FA-Series

[list style=”list4″ color=”green”]

- Fully Automatic Chute Bagger

- Cup Filling System

- Speed upto 40 bags/min

- Range available 10gm to 500gm

- Different pouch widths can be packed by

changing the forming chute - Suitable for free flow material with consistent

bulk density

[/list]

[divider_padding]

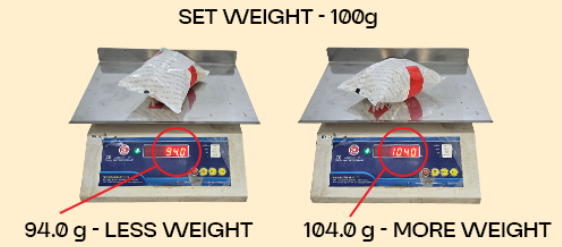

Cup Filler Machine is used to pack granular and powder items by volume. This machine has volumetric cups in which the material is filled from the top hopper. The volume of the cup is adjusted in a manner by the adjusting nut that the volume of the material in the cup can be adjusted and the final desired weight of material can be achieved.

As this is a volumetric cup filler the end accuracy in net weight depends on the consistency in bulk density of the material being packed. The volume of the cups can be maintained consistently by a rigid construction of the disc of the cup filling machine, however if the bulk density of the material is varying then the net weight also varies.

Another very important aspect of this machine is the flow characteristic of the material being packed. If the material does not have good flow characteristics then it poses two problems either the volumetric cups do not get filled completely or they may not get emptied completely, in both the cases there is a variation in the net weight of the pouch.

(Automatic Packing Machine – Mechanical Vs Pneumatic Machine)

So where is a cup filler more suitable?

It is ideal to use a cup filler where the weight variation is not a very high concern specially in products which are relatively cheap, also where the product has a good flow characteristic and high production speeds are required with a lower equipment cost.

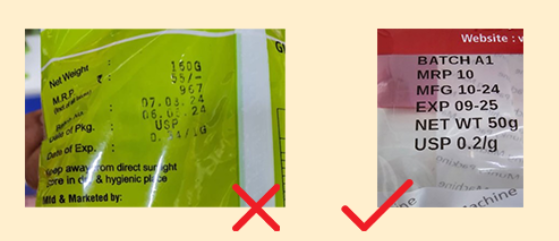

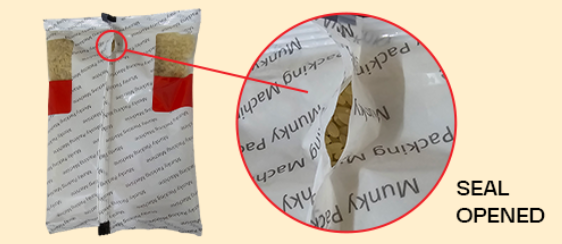

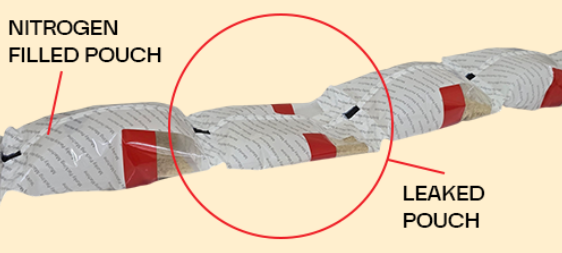

Cup filler machine is also easy to setup and involves more of mechanical parts and is easy to maintain. Our machine comes with double motors one for the rotation of disc and the other for the pulling of the laminate is recommended for a better control as both these motors have independent drives and sensors for motion they can be easily setup. The horizontal and vertical sealing are both done pneumatically. This ensures that the sealing is done properly and the temperature control is by PDI temperature controllers. Having a consistent temperature for sealing is critical to the quality of seal which ultimately affects the shelf life of the pouch. The machine comes with a camera for sensing the location of the eye mark. The batch coder prints the date code, mrp, lot code at the relevant location on the pouch.

[divider_advanced paddingTop=”19″ paddingBottom=”23″ thickness=”1″]

Specifications

[styled_table]

| Model | CF-050 | CF-100 | CF-500 |

|---|---|---|---|

| Weighing Range | 10-50gm | 50-100gm | 200-500gm |

| Speed (Bags/min) | 30-40 | 25-35 | 10-25 |

| Power Supply | Single / Three Phase | Single / Three Phase | Single / Three Phase |

| Load | 3.5 KW | 3.5 KW | 3.5 KW |

| Parameter Setting | Via Keyboard | Via Keyboard | Via Keyboard |

| Contact Parts-Stainless Steel | SS304 | SS304 | SS304 |

| Compressed Air | 150 LPM Approx. | 150 LPM Approx. | 150 LPM Approx. |

| Bag Width range (20-200 mm) | Yes | Yes | Yes |

| Bag Length range (70-280 mm) | Yes | Yes | Yes |

| Nitrogen Flushing | Yes | Yes | Yes |

| Batch Cutting- Programmable | Yes | Yes | Yes |

| Vertical Sealing – Pneumatic | Yes | Yes | Yes |

| Horizontal Sealing – Pneumatic | Yes | Yes | Yes |

| Output Conveyor Optional | Yes | Yes | Yes |

| Vibratory Feeder Optional | Yes | Yes | Yes |

| Batch Coding (Optional) | Pneumatic / Ribbon Coding | ||

| Display | Alphanumeric LCD Display 4 Rows, 20 Columns | ||

| Floor Area | 1500 x 900 mm | ||

| Bag Forming | Quick Change over Chute | ||

| Sealing | Heat Sealing with PDI Controller for all sealers | ||

| Room Ceiling Height | 9′ Min Clear Ceiling Height Required |

[/styled_table]

[divider_padding]