Kurkure Packing Machine

Kurkure Packing Machine requires a deeper understanding of the product. There are various products that form a part of puffed snacks like soya katori, corn puffs, kurkure etc. Soya katori packing machine, corn puff packing machine, kurkure packing machine, murmura packing machine, fox nut packing machine, makhana packing machine, soya puff packing machine all are examples puffed snack packing machine.

Puffed snack have different shapes and sizes. Moreover they are very light in weight and occupy more space ie volume and are light in weight.

Further the kurkure are fragile, if not handled properly in the machine then they tend to break.

The kurkure packing machine are packed usually in the range of 20gm to 100g or more, it should be possible to pack this weight range in the same machine.

The change over from one weight setting to the other should be easy and it should be possible to form pouches of different sizes in the same puffed snack packing machine.

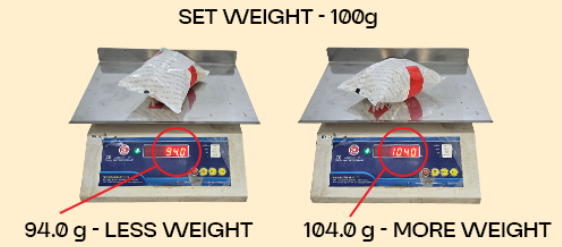

Both the manpower cost and the cost of raw materials is on a consistent increase. It is necessary to have a kurkure packing machine that optimises both the material saving and manpower saving during the packing process to keep up with the profitability levels. If the nett weight that is packed in each pouch is less then the distributors and dealers raise a complaint. To overcome this issue manufacturers are forced to pack higher quantity per pouch. If the upper level of the weight that is packed in the pouch is not controlled then it can affect the profitability adversely.

Connect with us for FREE Consultation or to Download Catalogue

*This information will remain confidential.

Solution – Kurkure Packing Machine

We manufacture packing solutions that fill on the basis of weight and packs the pouches automatically. The video given below gives a detailed description of the operation of the kurkure packaging machine

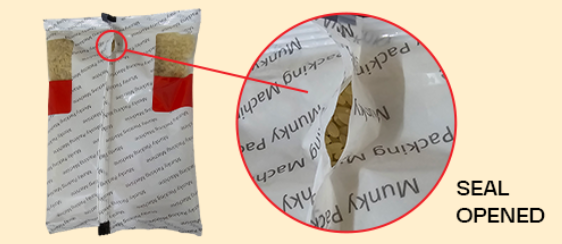

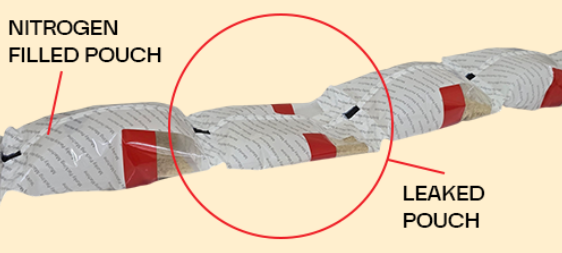

The same machine packs Multiple nett weights of puffed snack. The size of forming chute or forming collar changes with the sizes of pouch. Nitrogen filling is a user programmable feature.

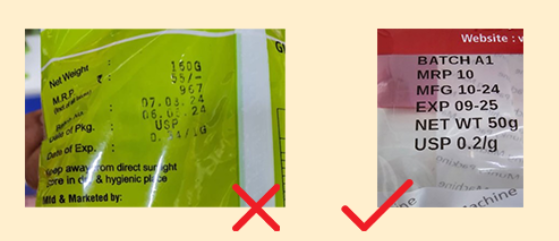

The batch coding unit can print multiple lines on the pouch at designated locations. The standard kurkure packing machine includes a pneumatic coder however the ribbon coding comes as an added accessory. This unit enables the user to print variable information like Nett Weight, MRP, Lot Code and date of manufacture.

The batch cutter prepares prepares multiple pouches per strip or single pouch at a time.

The number of weighing heads for the puffed snack packing machine can vary from one, two to four weighing heads. This gives the customer of selecting a machine that suits their speed and budget.

Owing to these reasons the volumetric fillers are losing ground to the weigh fillers in the long run and many manufacturers are discarding the volumetric fillers for granular items and opting for weigh fillers to run their production lines for packing kurkure.

Kurkure Packing Machine Price

Please contact us by clicking below link to get Kurkure Packing Machine Price.

*

![]()

+91-9599919442