Pouch packing machines are essential for efficient, hygienic, and cost-effective packaging in today’s fast-paced manufacturing world. Whether it’s food, spices, tea, or snacks, these machines are at the core of modern packaging solutions. But what exactly is a pouch packing machine, and how does it work? In this article, we’ll explore everything you need to know, including how munky packaging machine is transforming the packaging industry in india.

What is a Pouch Packing Machine?

Our pouch packing machine is an advanced packaging equipment used to fill and seal various products into flexible pouches. These machines are commonly used across food processing, pharmaceuticals, agriculture, and chemicals. There are different types of pouch packaging machines depending on the application and product type, such as:-

- Automatic pouch packing machines

- Vertical Form Fill Seal (VFFS) machines

- Multi-head weigher packing machines

- Liquid pouch packing machines

- Spice and powder packing machines

At Munky Packaging Machine, we specialize in manufacturing robust and efficient pouch packing machines for various industries, offering both standard and customized solutions.

How Does a Pouch Packing Machine Work?

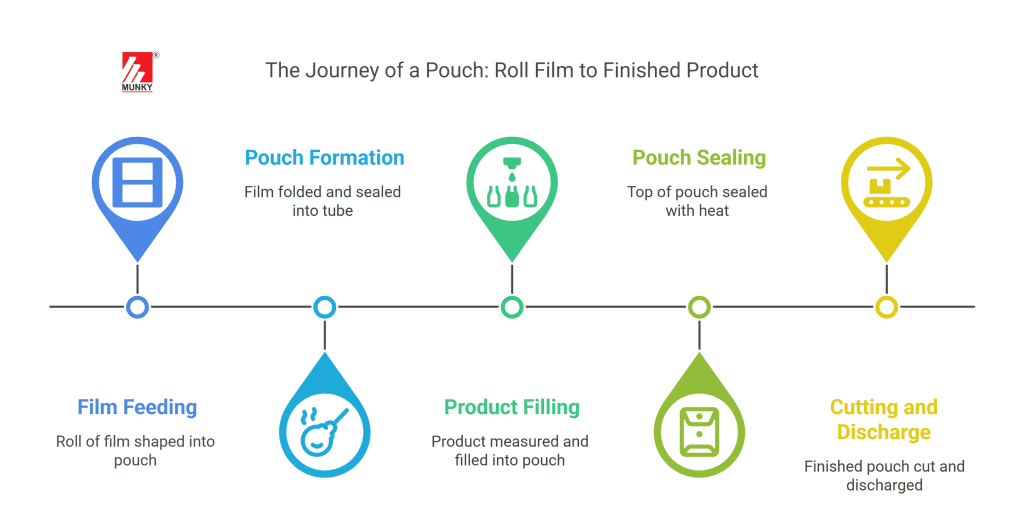

Though the exact working mechanism may vary by model, the typical process of a fully automatic pouch packing machine includes the following steps:-

1. Film Feeding

The machine pulls a roll of packaging film, which is then shaped into a pouch. This is done using forming collars in VFFS machines. The film is usually laminated and food-grade safe.

2. Pouch Formation

The flat film is folded and sealed vertically to form a tube. The bottom end is sealed to create a pouch.

3. Product Filling

Next, the product, whether solid, liquid, granules, or powder, is measured using a filling system like an auger filler, volumetric cup filler, or multi-head weigher, and then filled into the formed pouch.

4. Pouch Sealing

After filling, the top of the pouch is sealed using heat sealers. At the same time, the bottom of the next pouch is created.

5. Cutting and Discharge

The filled and sealed pouch is cut from the strip and discharged onto a conveyor or collection tray. The process then repeats for the next cycle.

This entire cycle is fully automatic and can operate at speeds of 30–100 pouches per minute, depending on the model.

Benefits of Using a Pouch Packing Machine

✅ Improved Efficiency

These machines greatly reduce human labour and increase packing speed, which is crucial for mass production.

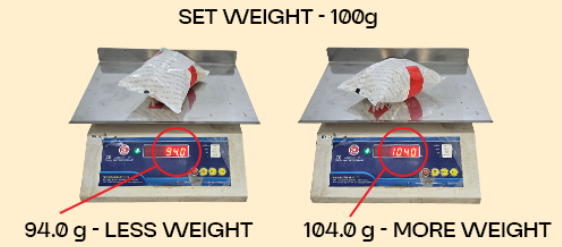

✅ Consistent Packaging

Uniform weight and size are maintained in every pouch, ensuring quality control.

✅ Versatile Packaging Options

They can pack various materials, including powders, liquids, solids, and granules.

✅ Cost Savings

By reducing product wastage and labour costs, these machines are a cost-effective investment.

✅ Hygienic and Safe

Touch-free operation ensures hygienic packaging, which is vital for food and pharmaceutical industries.

Industries That Use Pouch Packing Machines

- Food & Beverages:- Chips, snacks, pulses, rice, and frozen foods.

- Spices & Powders:- Turmeric, chili powder, masala blends.

- Liquids:- Milk, water, sauces, oil.

- Pharmaceuticals:- Tablets, powders, gels.

- Cosmetics:- Shampoo sachets, creams, and lotions.

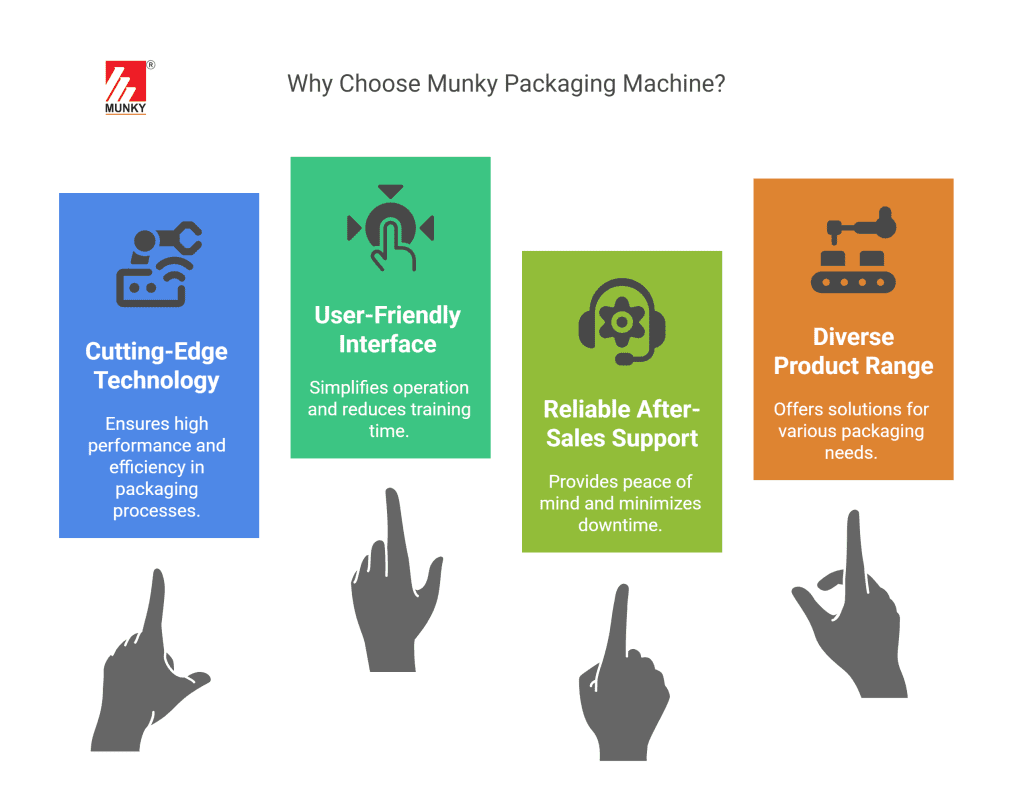

Why Choose Munky Packaging Machine?

At Munky Packaging Machine, we design and manufacture high-performance automatic pouch packing machines tailored for Indian industries. With cutting-edge technology, a user-friendly interface, and reliable after-sales support, we are one of the most trusted packaging machine manufacturers in India.

Our product range includes:-

- Snack packing machines

- Masala packing machines

- Tea pouch packing machines

- Liquid packing machines

- Puffed snacks packaging machines

Highlights of Munky Machines:-

- High-speed automation

- Minimal maintenance

- Energy-efficient designs

- Customizable for your product type and pouch size

Whether you are a small business or a large-scale manufacturer, Munky Packaging Machine has the right solution to scale your packaging needs.

Our Customers Reviews

See The Video :-

Don’t just take our word for it hear what our satisfied customers have to say. Watch this quick video testimonial from a real Munky Packaging Machine user sharing their experience, performance results, and why they recommend our machines.

Conclusion

A pouch packing machine is more than just a piece of equipment it is a smart investment that boosts efficiency, improves product presentation, and ensures hygiene. Understanding how it works and its various benefits can help you choose the right model for your business.

If you want to automate your packaging line, explore the reliable and cost-effective solutions from Munky Packaging Machine India’s trusted name in the packaging machinery industry.

FAQs

Q1. What exactly is a pouch packing machine used for?

A pouch packing machine is used for efficiently filling and sealing products like powders, liquids, solids, and granules into flexible pouches. It is widely used in food, pharmaceutical, and cosmetic industries.

Q2. Can a pouch packing machine pack both solids and liquids?

Yes, depending on the model. Munky Packaging Machine offers specialized variants for powders, granules, and liquid pouch filling.

Q3. Is a pouch packing machine easy to operate?

Modern machines from Munky are designed with user-friendly interfaces and minimal training requirements. Touchscreen panels and auto-diagnostics make operation easy.

Q4. What are the benefits of using a pouch packing machine over manual packing?

A pouch packing machine ensures faster packaging, consistent quality, hygiene, lower labor costs, and reduced wastage, making it a more profitable option in the long run.

Q5. How fast can a pouch packing machine operate?

The speed varies by model but generally ranges from 30 to 100 pouches per minute, ensuring high production output.

Q6. What industries commonly use pouch packing machines in India?

Industries such as snacks, tea, spices, pharmaceuticals, cosmetics, dairy, and chemicals heavily rely on pouch packing machines for fast and hygienic packaging.

Q7. How do I know which pouch packing machine is right for my business?

You should consider product type, packaging material, speed requirements, and your budget. Munky Packaging Machine provides free consultations to help you choose the ideal model.

Q8. Are pouch packing machines customizable for different pouch sizes and materials?

Yes, especially those manufactured by Munky. You can customize based on pouch size, laminate type, filling system, and sealing requirements.

Q9. How much does a pouch packing machine cost in India?

The price can range from ₹1.5 lakh to ₹15 lakh depending on automation level, model type, speed, and features.

10. Does Munky provide service and support after the machine is installed?

Yes. Munky Packaging Machine offers complete after-sales service, AMC plans, operator training, and remote troubleshooting to ensure uninterrupted performance.